Suggested Machine Model

The 1625 model is the preferred choice for 80% of customers in the foam insert manufacturing sector, featuring a 1600x2500mm work area. If you need a larger size, you can opt for 1600x3000mm or 1600x4000mm options. We also offer custom-built sizes, including a 2500x3000mm work area, to meet specific requirements.

Multi-functional Cutting

It is highly versatile, featuring pneumatic cutting tools, robust 400W electric cutters, and ultra-fast 800W milling cutters. It can handle materials up to 120mm thick and excels in carving and cutting EPE and EVA foams with hardness between 35° and 80°. Ideal for various industrial applications, it ensures precision and efficiency.

Offer Custom Production

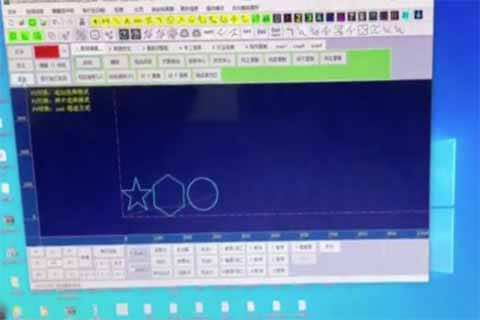

With an oscillating knife Foam cutting machine, you can effortlessly tailor the shape and size of your foam inserts to meet your precise needs. This flexibility allows for bespoke packaging solutions, ensuring that each insert fits perfectly and efficiently within your custom packaging requirements.

China Top Quality

Our oscillating knife cutter is built with top-quality components, including Japanese Mitsubishi motors, French Schneider electrical systems, Japanese Omron safety features, and Taiwanese HWIN rails. We ensure that only the finest parts are used to deliver reliable and high-performance cutting solutions.